Fixed Wire Testing – Your Legal Obligation

Deterioration is inevitable with age and electrical installations are not immune to this, requiring inspection and testing at regular intervals to ensure satisfactory condition and continued use.

Periodic inspection and testing reveal if electrical circuits or equipment is overloaded, highlights defects and identifies potentially lethal risks and fire hazards. Neglecting faulty electrical equipment and your building’s fixed wiring could result in injury, damage to your building, lost income and fines if found in breach of your statutory legal responsibilities.

Timescales

The Electricity at Work Regulations state all electrical systems and equipment used in the work area should be in a safe condition. This means that the testing and inspection schedule must be implemented at all workplaces. The frequency of the inspection depends on the type of installation and what it is being used for, this varies between 3 months and 10 years. Detailed below in accordance with the guidelines laid down within the Institution of Electrical Engineers Wiring Regulations BS7671:2008 (as amended) and other relevant legislative guidance notes.

Thermographic Surveys

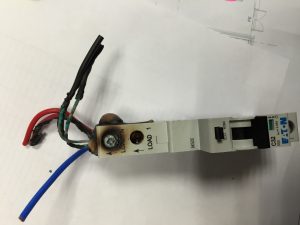

Evidencing the importance of these inspections, the picture to the right sh ow an RCBO discovered on a recent project obviously overheating and amazingly still in operation.

ow an RCBO discovered on a recent project obviously overheating and amazingly still in operation.

Lindale Building Services offers the additional reassurance of avoiding similar hazards via our thermal imaging service. This service is offered as an enhancement to our current electrical circuit testing, identifying any hidden hazards not seen to the naked eye. Utilising infrared thermographic equipment, our electronic thermographic survey report provides a clear indication of the suspected cause of the fault, the severity of the problem and the remedial action required to repair.

The benefits of using Lindale Building Services Ltd to conduct an electrical thermographic survey include:

- Power is not interrupted during a survey

- This is a predictive maintenance technique reducing the risk of fire due to early detection of any faults

- We only use high resolution thermal imaging equipment which allows us to detect faults on smaller components and allows us to keep a safe distance from potential faults

- Insurance companies provide positive feedback on our service and follow up activities

- There is potential to gain a reduction in your business insurance by having a thermographic survey conducted

Lindale Building Services is accredited by the National Inspection Council for Electrical Installation Contractors (NICEIC) and our services are underpinned by our ISO 9001 certified Quality Management System. Get in touch and see how we can help you.